| Product description | Applications area | Type and parameter | Schematic diagram |

|---|

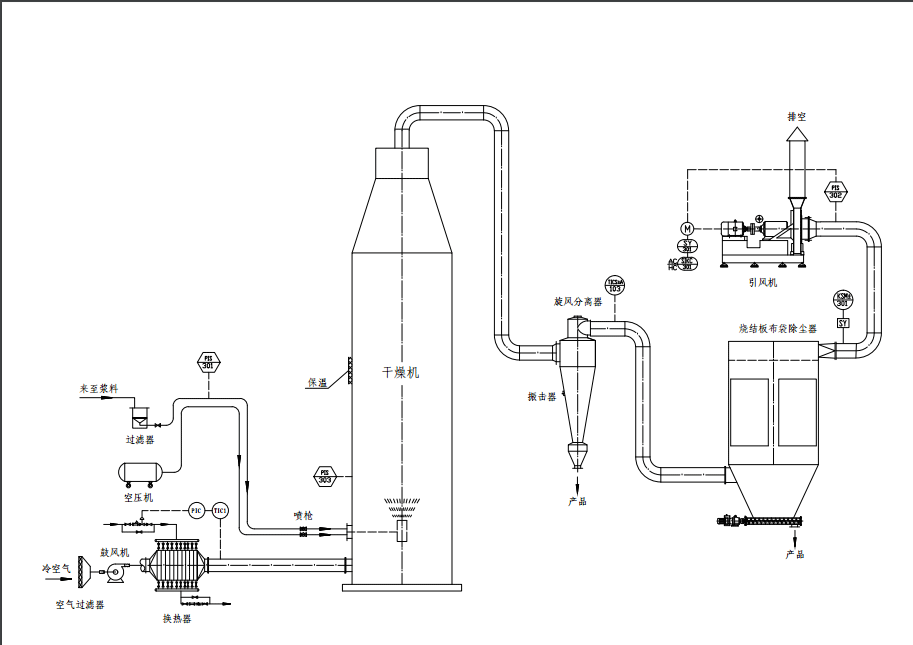

The air flow spray drier nozzle is arranged at the bottom of the drying tower, and the material liquid and the hot air are used to complete the drying process from bottom to top, which is suitable for the material with good temperature resistance performance.

Dry cold air through the filter enters the heater for heating into the drier, wet material by pressure pump to the dryer in the nozzle, the nozzle will be liquid ejected into mist, two are fully mixed, mist of liquid with contact with hot air, due to the heat and mass transfer in a large area, rapid material in most of the water evaporated, the rest of the water evaporated in the sufficient drying time, products collected in the cyclone separator, a small part of the fly by bag filter material. System into a negative pressure operation, the material is not through the fan, tail gas through the draught fan evacuation.

The spray structure is simple, the maintenance is convenient, the operation cost is low. The drying machine has high evaporation intensity, large production capacity, uniform moisture content and stable quality.

The device is widely used in the fields of dyestuff, organic pigment, dye intermediate, fertilizer, assistant, pesticide, catalyst, detergent, ceramic, rubber, medicine, food and other fine chemical industry.

|

model |

QPG-800 |

QPG-1000 |

QPG-1200 |

QPG-1500 |

QPG-1800 |

QPG-2200 |

|

Water evaporation rate(kg/h) |

220 |

345 |

500 |

750 |

1125 |

1680 |

|

Equipment diameter.(m) |

0.8 |

1.0 |

1.2 |

1.5 |

1.8 |

2.2 |