| Product description | Applications area | Type and parameter | Schematic diagram |

|---|

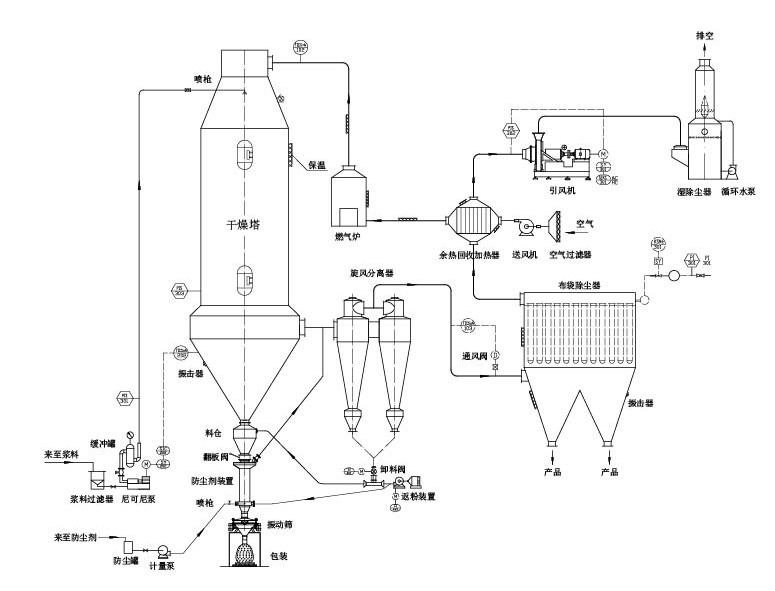

LPG series pressure type spray dryer system and flow type spray dryer, the product is fine particles. Materials after atomization has great specific surface area, in an instant drying; atomizer for pressure type, embedded with artificial corundum, tungsten carbide material using long service life and convenient operation. At the end of the tower, the structure of the reduced velocity and the material non stick wall are adopted.

The device can be additionally provided with advanced thin powder recovery device, fine powder after collector and distributor, to the cyclone separator or a bag type dust catcher with the subdivision re recycling granulation, so that products into grain rate of more than 95%.

Can also be added to the dust agent injection mixing device, so that the spray drying and spray dust agent two processes once completed, the product is more than 4A dust level.

In order to improve the energy utilization, the waste heat recovery device can be added to reduce energy waste and create economic benefits.

The device is widely used in the fields of dyestuff, organic pigment, dye intermediate, fertilizer, assistant, pesticide, catalyst, detergent, ceramic, rubber, medicine, food and other fine chemical industry.

|

model |

LPG-1800 |

LPG-2200 |

LPG-2400 |

LPG-2800 |

LPG-3200 |

LPG-3600 |

|

Water evaporation (kg/h) |

80~150 |

125~220 |

150~270 |

180~360 |

260~470 |

330~600 |

|

Equipment diameter (m) |

1.8 |

2.2 |

2.4 |

2.8 |

3.2 |

3.6 |

|

model |

LPG-4000 |

LPG-4500 |

LPG-5000 |

LPG-5500 |

LPG-6000 |

LPG-7000 |

|

Water evaporation (kg/h) |

400~730 |

510~930 |

630~1150 |

770~1400 |

800~1600 |

900~2000 |

|

Equipment diameter (m) |

4.0 |

4.5 |

5.0 |

5.5 |

6.0 |

7.0 |