| Product description | Applications area | Type and parameter | Schematic diagram |

|---|

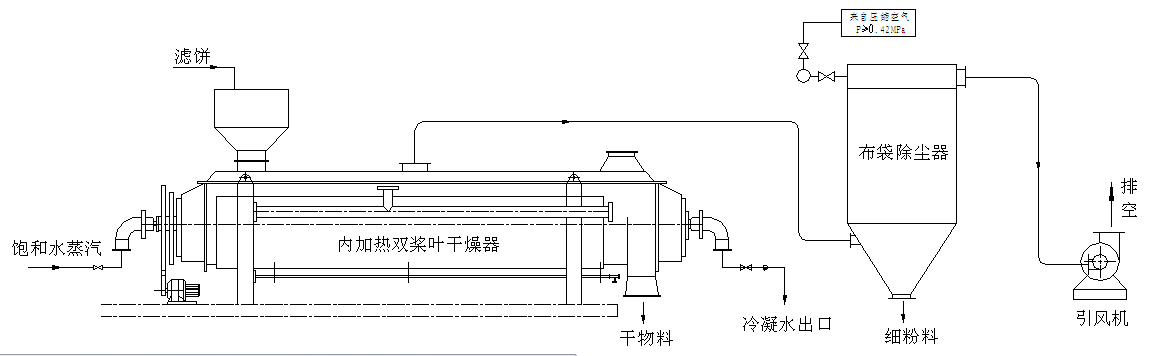

Paddle dryer is in the drying chamber set a variety of structure and shape of blade to stir the dry material and the material under the stirring paddle stirring continuous and wall heat transfer surface of the dryer and the contact of the heating body, accelerate the transfer speed and the moisture evaporation, achieve the purpose of drying, this kind of equipment is called paddle dryer, also called the agitating type dryer.

Dryer equipment characteristics:

1, the equipment structure is compact, the area is small, reduce infrastructure investment.

2, heat utilization rate is high, the heat is not needed by the hot gas supply directly, reduce the heat loss, heat utilization rate can be as high as 80%~90%, the blade speed is low 10~40rpm, reduce dust.

A self purification ability 3, wedge-shaped blade, blade can improve the heat transfer effect. Dispersion force generated by the rotating blade tilt area granule or powder layer combined action, can automatically remove attached on the inclined plane of the material; blade between counter rotating alternating segmented compression and expansion, heat transfer near the surface of the material is intense vibration, improve the heat transfer effect. Higher heat transfer coefficient for 85~350w/m2 and K.

4, less gas consumption, only a small amount of gas used for carrying out the moisture, as long as to meet in the dryer operating temperature, condensation drying system. In addition, less gas consumption, gas velocity and low, less dust entrained by the gas, the gas dust after drying is convenient, can reduce the size and specifications of auxiliary equipment, saving equipment investment.

5, material drying heat is not relying on carrier directly in contact with the material to be heated, but to the hollow blade and equipment clip set of input heat carrier, after the wall heat conduction on the drying process to provide heat, it reduces the heat loss caused by gas heating, improve the utilization rate of the heat. Therefore, it belongs to energy saving type drying equipment.

6, material adaptability is wide, the product is dry and even. Dual variable overflow plate height adjustable material retention. Adjust the feeding speed, the shaft speed and the carrier temperature, and control the retention time of the material in the dryer to reach the requirement of drying moisture.

7, filling coefficient is high, up to the full volume of 70~80%, up to 85%, the moisture content from up to 75% to 0.1% below, can be applied, the product is uniform, continuous discharge, and intermittent discharge.

8, negative pressure operation, but it is not suitable for high vacuum operation.

9, can be used for cooling and heating.

10 suitable for drying heat sensitive materials, can be used for the recovery of solvent drying process.

The device is widely used in alcohol residue, Oxytetracycline Residue, erythromycin slag, powdered coal, bark powder, clay, kaolin, iron oxide yellow, trisilicate magnesium, alumina, H-acid, mycelium, nitroaniline, sodium cyanide, pesticide, indigo, ASN resin, antioxidant 1010, accelerator DM,.

|

model |

KJG—3 |

KJG—8 |

KJG—12.5 |

KJG—25 |

KJG—50 |

|

Heat transfer area(m2) |

3 |

8 |

12.5 |

25 |

50 |

|

Rotational speed(r/min) |

6—24 |

5—20 |

5—20 |

5—20 |

4—16 |

|

Power (Kw) |

3 |

4 |

5.5 |

11 |

18 |

|

Effective volume(m3) |

0.065 |

0.49 |

0.94 |

1.65 |

3.15 |

|

Water evaporation intensitykg/(m2•h) |

10—60 |

||||

|

Shape dimension(mm) |

3300 ×420×900 |

4820 ×880×1200 |

5780 ×1120×1480 |

6860 ×1420×1840 |

3800 ×1420×2050 |

|

Equipment weight(kg) |

1600 |

2100 |

2300 |

2700 |

3600 |