| Product description | Applications area | Type and parameter | Schematic diagram |

|---|

Dryer's brief introduction:

Flash dryer is a kind of vertical fluidized bed dryer with a rotating grinding device, can complete the material at the same time of drying, crushing, grading, and so on. At the bottom of the equipment body for cylindrical dryer, crushing section with a blender. Agitator rotational speed adjusted by external motor.

Hot air from the bottom of the slit into the cylinder, suffer the effect of stirring paddle, strong rise in rotating airflow and solid for heat and mass transfer in an instant dry making materials. Widely used in dye, pesticides, mineral, dry filter cake of organic matter.

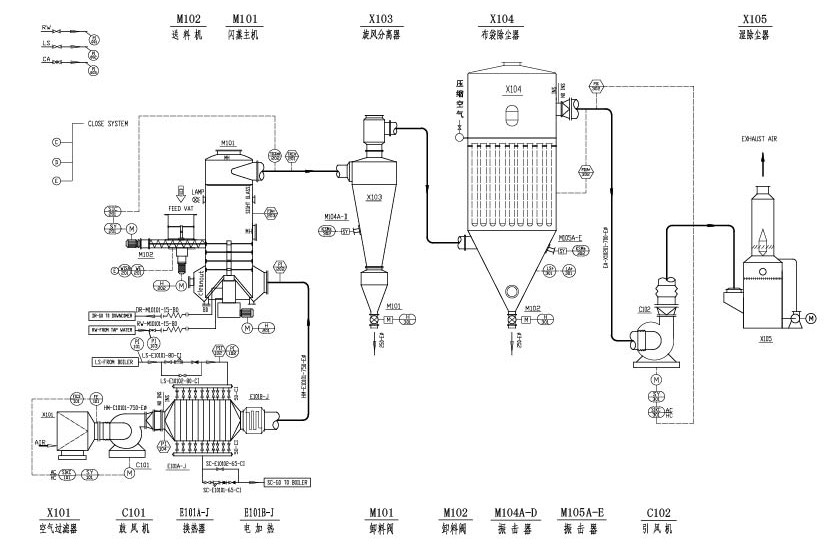

The composition of drying machine:

Flash dryer by feeder, screw feeder, dryer, drying by the hot air distributor, mixer, grading ring, drying room, etc) trap, fan, heater, etc.

The structure characteristics of the drying machine:

1, dry bottom design is an inverted pyramid structure, can make the dry gas flow area grows from bottom to top, so that the bottom of the gas velocity is opposite bigger, the upper gas velocity is relatively small, and the lower part of big particle material is always keep fluidized state. In addition, the inverted cone structure also shorten the length of the stirring shaft bracket part, increase the reliability of the rotation, can also prevent the bearings work in high temperature environment, so as to prolong the service life of the bearing.

2, mixer mixing on the tooth is equipped with scraper, material by mixing crushed at the same time, it is easy to be thrown to the wall, if not timely scrape, can make the material stick on the wall, will lead to abnormal operation. Stirring tooth on the scraper, it can be put into the wall material binding off before, to ensure the normal operation.

3, drying chamber of the grading ring, can not dry and large particles materials blocking, carry out crushing and drying, narrow particle size cloth, to ensure product moisture content consistent with the requirements.

4, cold hot air at the entrance to set on the conical bottom protection, hot air began to contact with the material, generally close to the temperature of hot air, far higher than that of bed temperature, operation unavoidably appear a few material in hot air into the gap near the cementation, residence time is long, can make the material deterioration, and even melt material, in order to avoid this phenomenon, add local cold wind protection, can lower the temperature of the point, make the normal operation, ensure the quality of the product.

5, the special structure of the feeder and screw conveyor, it can be intermittent flow block into controlled continuous material flow, has six straight root in spiral feeder losing wall layering, ensure uniform loading.

6, material in the dryer, and at the same time to complete the process of crushing, scattered, drying, classification, multi-purpose reach level, wide application scope.

7, because the material is centrifugal shear, collision, friction and the particles are highly fragmented and gas-solid relative speed between the larger, enhanced heat transfer and mass transfer, make the equipment production high strength.

8, dry gas in the drying chamber to form strong rotating airflow, the erosion of wall material to produce strong column out of the role, eliminates the wall sticking phenomenon.

9, feed and hot blast temperature can adjust and control, adjust the speed of the screw conveyor, can meet the requirements of the final moisture content.

10, the system shows negative pressure operation, eliminates the pollution of the environment.

11, short drying time, to dry heat-sensitive materials can be directly, and ensure the quality.

12, the machine structure is compact, cover an area of an area small, easy to operate.

13 key part, this machine can be replaced, the key control parameters can be adjusted, adjust the stay time, material can be used in a variety of materials.

14, the machine design with fluidization technology, spray technology, hydrocyclone technology as the foundation, to drying theory research and scientific experiments, production effectively, to optimize design.

The device is widely used in the fields of dyestuff, pesticide, mineral, filter cake like organic matter, inorganic matter, ceramics, pigments, food and other fine chemicals.

|

model |

XSG-400 |

XSG-500 |

XSG-650 |

XSG-800 |

XSG-1000 |

XSG-1200 |

XSG-1400 |

|

Water evaporation(kg/h) |

19~38 |

35~75 |

65~125 |

80~185 |

160~350 |

180~400 |

320~600 |

|

Equipment diameter (m) |

0.4 |

0..5 |

0.65 |

0.8 |

1.0 |

1.2 |

1.4 |

|

Effective height(m) |

2.0 |

2.5 |

2.5 |

3.0 |

3.5 |

3.8 |

4.0 |