| Product description | Applications area | Type and parameter | Schematic diagram |

|---|

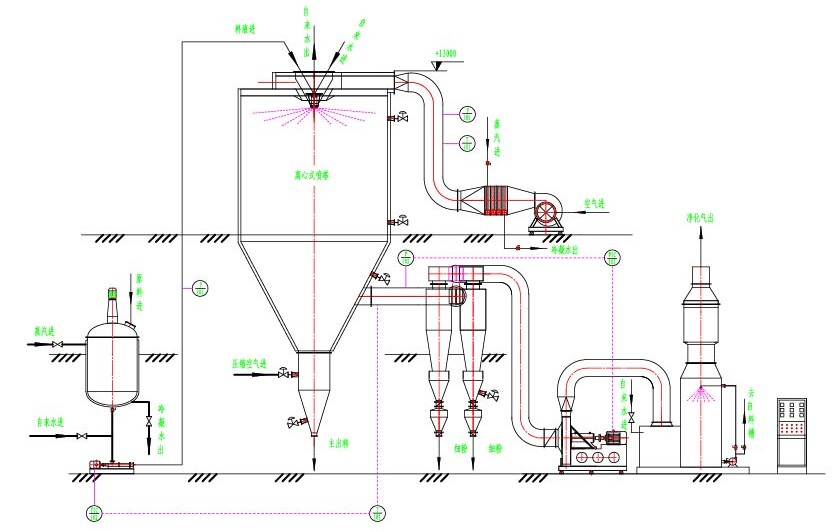

Centrifugal spray drying process of atomization and some special, the spray drying is the centrifugal nozzle, liquid in high speed rotary disc (peripheral speed 90~140m/s or higher by centrifugal force effect, from the intraday thrown and atomization. Atomization mechanism: when the liquid material is sent to the high-speed rotation of the disk, due to the centrifugal force of the turntable, the liquid in a rotating surface stretching film and with increasing speed to the edge of the disk motion, away from the disk edge is liquid atomization. The mechanism is still in the shape, diameter, rotational speed, feed rate, and the properties of the material, which is still in the shape of the disk.

The droplet size and spray uniformity of the centrifugal nozzle are mainly determined by the velocity of the rotating disk and the thickness of the liquid film, and the thickness of the liquid film is related to the treatment of the solution. The non-uniformity of the spray decreases with the increase of the disc velocity. That is to say, the disc speed is large, and the disc speed is low.

The device is a parallel flow operation, which can be directly obtained from the feed liquid.

The device is widely used in the fields of food, pesticide, ceramic, fine chemical industry, etc..

|

model |

LXG-100 |

LXG-200 |

LXG-280 |

LXG-320 |

LXG-350 |

LXG-400 |

LXG-450 |

LXG-550 |

LXG-700 |

LXG-800 |

Water evaporation(kg/h) |

10 ~20 |

20 ~25 |

50 ~100 |

90 ~120 |

120 ~180 |

160 ~240 |

220 ~350 |

400 ~650 |

580 ~1200 |

630 ~2000 |

|

Equipment diameter (m) |

1.5 |

2.0 |

2.8 |

3.2 |

3.5 |

4.0 |

4.5 |

5.5 |

7.0 |

8.0 |