| Product description | Applications area | Type and parameter | Schematic diagram |

|---|

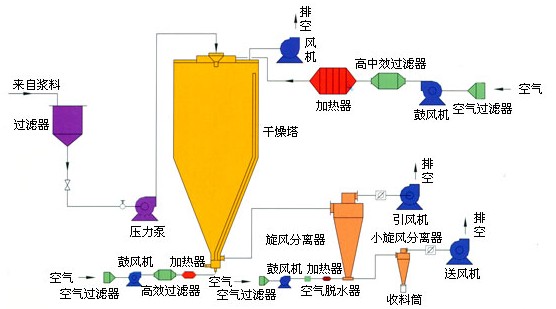

Cold air through air filter enters the heater for heating, hot air by induced draft fan into dryer at the top of the hot air distributor, through the hot air distributor after hot air evenly enters the drying tower, and spiral motion. Feed pump and the liquid will be sent to dryer at the top of the centrifugal sprayer, the liquid material is sprayed into tiny droplets of mist; to greatly increase the surface area of the feed liquid and contact the hot air water instantly evaporation, in a very short time drying dry goods. After entering the cyclone separator, the dry product is separated from the air, and then is separated from the bottom of the cyclone separator and then sent to the small cyclone separator.

Drug (Chinese Medicine) variety, extract nature difference, especially the extraction of polysaccharide solution is even more so. To avoid adhesion material in drying chamber wall due to long time heating and softening and deterioration, special design drying chamber wall and top clamp sets of air cooling system and air blowing device for continuous purge, material does not occur in the drying chamber wall adhesion, increase the yield of products, but also improve the rate of equipment utilization, saving energy.

For the pharmaceutical production of GMP requirements, the equipment and materials, and air contact with the use of SUS304 stainless steel production. The device solves the problems of sticking wall, moisture absorption and agglomeration of the traditional spray drying machine, and is suitable for the drying of the extracting solution of the traditional Chinese medicine with low softening point and high sugar content.

The device can dry products: polygonatum, angelica, antlers, hawthorn, red dates, wolfberry fruit, chuanxiong.

|

model |

ZLG-5 |

ZLG-20 |

ZLG-50 |

ZLG-100 |

ZLG-150 |

ZLG-200 |

ZLG-300 |

|

Dryer diameter,mm |

1200 |

2200 |

3000 |

3800 |

4400 |

4800 |

5500 |

|

Inlet air temperature,℃ |

180~200 |

||||||

|

Exhaust air temperature,℃ |

80~100 |

||||||

|

Evaporation water,kg/h |

5~7 |

15~30 |

40~60 |

80~120 |

140~160 |

180~220 |

250~350 |