| Product description | Applications area | Type and parameter | Schematic diagram |

|---|

LSD type spray dryer is designed to provide for the laboratory test of mini spray dryer, the intensity of the same volume is adopted in the design process, the principle of geometric similarity design, can be effectively simulated production conditions; so it can provide reliable data for production.

The device and system configuration and production equipment, similar to the process, but also has the advantages of compact device, modeling novel device used in all SUS304 stainless steel made by the polishing treatment, can be moved freely, with convenient disassembly and assembly, convenient cleaning, is the ideal laboratory spray dryer.

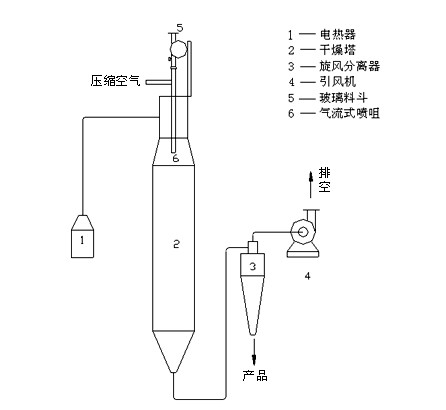

Dryer working principle:

From glass hopper of the slurry, is sprayed out through a nozzle to spray flame droplet, evaporation of surface moisture and contact the hot air, and liquid droplet of water is to the surface migration, the liquid drops to keep the surface of the wet bulb temperature, this is drying of the first stage of constant rate drying. Then the droplets of water gradually decreased and migrate to the surface of the water is gradually reduced, the droplet surface gradually form a hard shell, which hinder the internal moisture migration, which is drying in the second stage, reducing dry, until finally complete the drying rate and in the cyclone gas solid separation. The system operates under the negative pressure condition.

The device adopts the nozzle as the air flow type nozzle, and the 0.2-0.4MPa air is needed to spray the feed liquid, and the feed is controlled by the plug of the glass hopper.

1

|

Tower diameter(mm) |

Tower capacity(M3) |

Tower(mm) |

Assembly machine tile number(Kw) |

Evaporation capacity (L/hr) |

Inlet temperature(℃) |

outlet temperature(℃) |

Column pressure(Pa) |

|

Φ400 |

0.18 |

1850 |

9.1 |

2(max) |

200(max) |

60 |

-100 |